Product Code: TC3-SS TOYOCONNECTOR-TC3-SS

- RoHS2 Certified

TOYOCONNECTOR TC3-SS Coupling (TOYOSILICONE Hose Series Dedicated)

Couplings for factory pipe lines (Toyox hose genuine couplings)

TOYOCONNECTOR is a hose manufacturer designed coupling exclusively for TOYOX hoses.

* TOYOSILICONE Hose Series Dedicated.Check the compatible hoses.

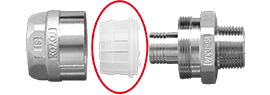

(Material: SUS/Cap nuts type/Couplings Specification: Male Thread)

It is a hose coupling that is useful in improving productivity, safety and energy saving properties by preventing problems such as insufficient flow, fluid leakage and hose disconnection between the hose and coupling, and improving the installation process of the hose to the coupling.

For better productivity, safety and energy saving properties, we recommend that you select hoses suitable for your specific application and conditions.

* It is the successor to the previous models TCSBS.

◆ Click here for a list of other hose fittings

◆ Click here for SS male thread hose fittings except than silicone hoses

◆ Click here for Plastic male thread hose fittings except than silicone hoses

◆ Click here for Brass male thread hose fittings except than silicone hoses

Important

*When installing, do not use a liquid screw sealant containing a solvent.

- Guidance

- Coupling Design Chart

- List of Compatible Hoses

| Connection Surface | Connection Method | Inner Diameter for Hose (mm) / Coupling Specification |

|---|---|---|

| Hose Side | Cap Nut | 9,12,15,19,25 |

| Device Side | Male Thread | R3/8,R1/2,R3/4,R1 |

| Product no. | : | TC3-SS |

|---|---|---|

| Fluids | : | Air Chemicals Oils Water (Non-drinkable) |

| Primary Material | : |

SUS |

| Materials Detail | : | Cap nut: SCS13 (SUS304 equivalent) Nipple: SCS16 (SUS316L equivalent) Sleeve: PVDF |

| Functionality | : | Easy to installEnergy savingPrevents leakage and disconnectionReusableStandardization of work |

| Certification | : |

RoHS2 (RoHS Revised) Certified |

Feature:

-

Resistant to corrosion

SCS 16 stainless steel is used, equivalent to SUS 316L. Superior resistance against rust and prevents steel leaching.

-

Prevents leaks and disconnections

The unique construction allows the hose to be securely inserted to the base of the coupling, preventing hose disconnections and fluid leaks.

-

Time savings

Hose insertion and removal is easy for increased efficiency.

-

Standardization of work (hyojunka)

Fasten the cap nut fully to complete the operation.

Hose insertion is simple and can be performed reliably and consistently no matter who does it. -

Reduced pressure loss

There is less fluid leakage, and with a larger effective surface area (hole diameter) than a barb fitting, there is less pressure loss.

-

Waste reduction

Coupling units can be reused, reducing waste and cutting costs.

-

Resistance to vibration

Hose problems due to leaks and disconnections caused by vibration are prevented, and earthquake and other disaster preventive maintenance, as well as restoration work after a disaster, are made easy.

-

Works with a variety of fluids

The nipple and hose end fitting are integrated, and the construction prevents the plastic part of the sleeve inside the coupling from coming into contact with liquid. Can be used with fluids resistant to stainless steel.

Related Videos:

-

Comparison of pressure resistance and safety

-

Comparison of attachment workability

-

Energy Savings Comparison

Worksite Improvement Case Studies

-

Significantly increased productivity and safety by preventing hose degradation and coupling disconnection/leakage.

-

The steam hose is heavy, so the cleaning work is tough. In addition, foreign matter intrusion due to inner hose deterioration is a concern

-

An over-tightened clamp cuts the hose, resulting in a water leak

-

Water leaks from the hose and coupling are a concern after years of use

Note: Because of the presence of threads, this is not appropriate for sanitary hoses (such as used for foods).

Use for foods may result in safety issues in the product.

| Part Number | Thread Specification | Dimensions (mm) | Weight | Packing Unit | ||||

|---|---|---|---|---|---|---|---|---|

| L | Φd1 | HEX1 | HEX2 | g | pc | |||

|

TC3-SS9-R3/8 | R3/8 | 48.0 | 6.9 | 30.0 | 24.2 | 133 | 20 |

| TC3-SS12-R1/2 | R1/2 | 53.0 | 10.1 | 32.0 | 27.0 | 178 | 20 | |

| TC3-SS15-R1/2 | R1/2 | 55.0 | 13.3 | 36.0 | 30.8 | 217 | 20 | |

| TC3-SS19-R3/4 | R3/4 | 59.5 | 16.9 | 41.0 | 35.8 | 290 | 10 | |

| TC3-SS25-R1 | R1 | 66.0 | 22.8 | 50.0 | 43.8 | 438 | 10 | |

Nipple: SCS16 (SUS316L equivalent)

Sleeve: PVDF

| Compatible Hoses : 6 | Hoses Name | TOYOSILICONE HOSE | TOYOSILICONE-S HOSE | TOYOSILICONE-P HOSE | HYBRID TOYOSILICONE HOSE | TOYOSILICONE STEAM HOSE | TOYOSILICONE THERMO HOSE | |

|---|---|---|---|---|---|---|---|---|

Material : SUS Material : SUS | Primary Material | Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | |

| Functionality | Chemical Resistant Cold Resistant Flexible Heat Resistant Low Elusion Low Odor No Waste Sorting Required Oil Resistant (Animal and Vegetables) Pressure | Break Proof Chemical Resistant Cold Resistant Flexible Heat Resistant Low Elusion Low Odor Oil Resistant (Animal and Vegetables) Pressure Vacuum | Break Proof Chemical Resistant Cold Resistant Flexible Heat Resistant Low Elusion Low Odor No Waste Sorting Required Oil Resistant (Animal and Vegetables) Pressure Vacuum | Break Proof Chemical Resistant Cold Resistant Flexible Heat Resistant Low Elusion Low Odor No Waste Sorting Required Oil Resistant (Animal and Vegetables) Pressure Vacuum | Cold Resistant Flexible Heat Resistant Low Elusion Low Odor No Waste Sorting Required Pressure | Chemical Resistant Cold Resistant Flexible Heat Resistant Low Elusion Low Odor No Waste Sorting Required Oil Resistant (Animal and Vegetables) Pressure | ||

| Product no. | TSI | TSIS | TSIP | HTSI | TSISTM | TSITH | ||

| Certification | FDARoHS2 Certified | FDARoHS2 Certified | FDARoHS2 Certified | FDARoHS2 Certified | RoHS2 Certified | RoHS2 Certified | ||

| Product Code | Compatible Hoses Inner Diameter(mm) | Coupling Specification |  |  |  |  |  |  |

| TC3-SS9-R3/8 | 9 | R3/8 | ◯ | - | - | - | ◯ | ◯ |

| TC3-SS12-R1/2 | 12 | R1/2 | ◯ | - | ◯ | ◯ | ◯ | ◯ |

| TC3-SS15-R1/2 | 15 | R1/2 | ◯ | - | ◯ | ◯ | ◯ | ◯ |

| TC3-SS19-R3/4 | 19 | R3/4 | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| TC3-SS25-R1 | 25 | R1 | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| Replacement Sleeve Set | |

|---|---|

|

|

| Part Number | Packing Unit |

| pc | |

| TC3-SS9-S | 20 |

| TC3-SS12-S | 20 |

| TC3-SS15-S | 20 |

| TC3-SS19-S | 10 |

| TC3-SS25-S | 10 |

Sleeve : PVDF

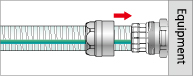

Attachment Method

| 1 | First attach the nipple to the machine. |  |

| 2 | Place the sleeve on the nipple. *Check to ensure that the sleeve pins and the nipple pin holes are in alignment. |

|

| 3 | Pass the hose through the cap nut and insert the hose to the back of the nipple to ensure the sleeve does not become displaced. *Ensure the assembly is secured tightly. |

|

| 4 | Fasten the cap nut until no gap remains. |  |

Attachment Tool

Use a wrench such as a regular adjustable or monkey wrench to finish tightening. Do not, however, use a pipe wrench as it will damage the nut portion.